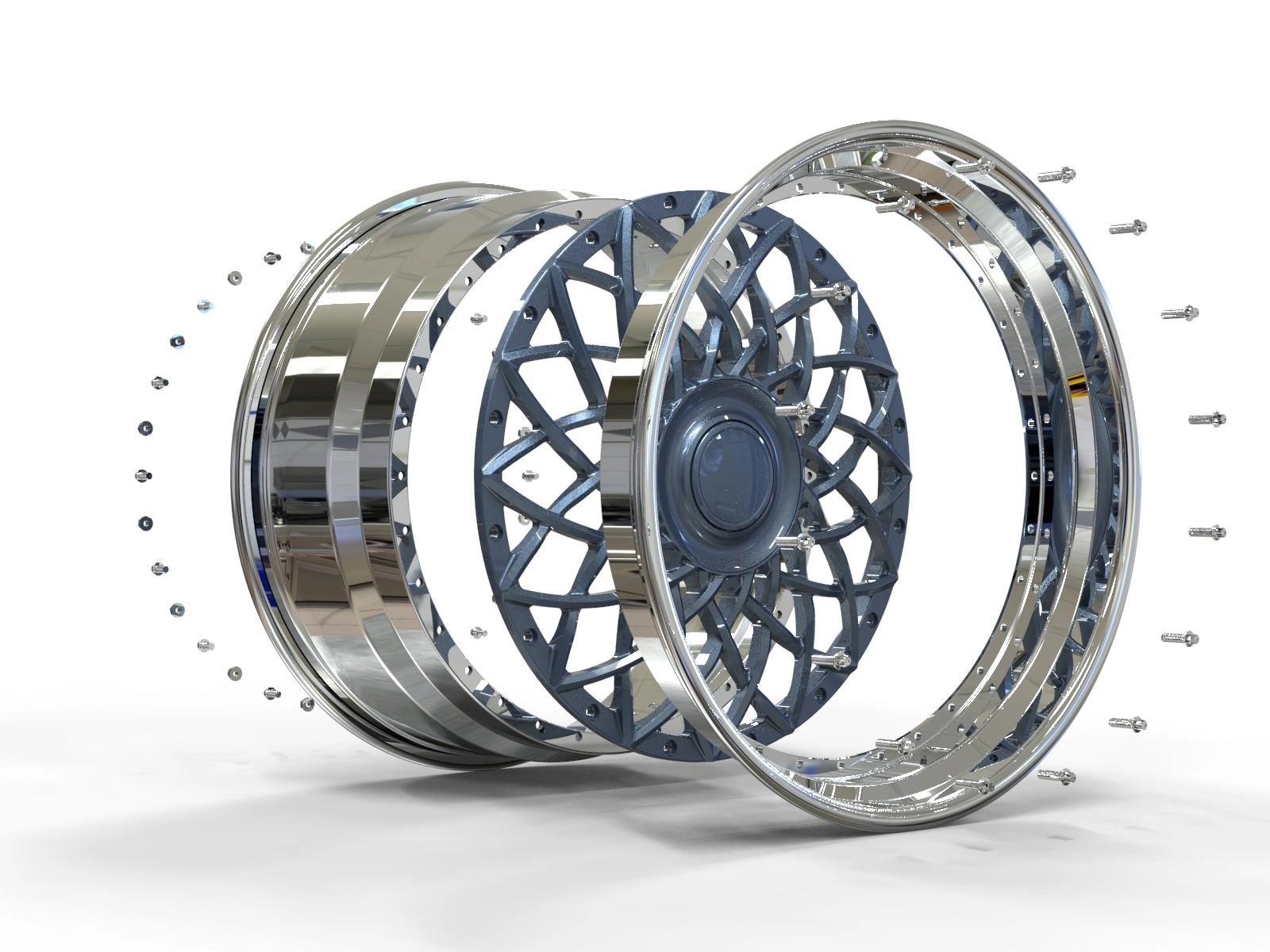

Three Piece Car Wheel

The three-piece wheels are

- made up of three parts, a center, an inner barrel and an outer barrel (lip) which provides protection and stability;

- usually custom made and hence good for fitment;

- strongest, lightest, stiffest, most durable with low rotational inertia if they are made by forging.

Product Details

These are the most common types of wheels that you have seen frequently on the road. Simply put one-piece wheels are made by casting molten aluminum into a mold, a single piece of metal.

The process consists of the material being either flow formed, pressure cast or forged. Cast and forged refer to how the wheel was manufactured, which in turn will determine the wheel’s performance characteristics and its price.

Cast wheels are manufactured by adding molten magnesium or aluminum alloy into a mold where it cools and takes shape.

Forged wheels are made from a solid block of alloy which is heated and subjected to immense pressure to create the wheel’s form and shape before it is finished on milling and CNC machines.

Because of how they are manufactured, forged wheels have more strength compared to wheels that are manufactured by casting.