Motorcycle Wheels

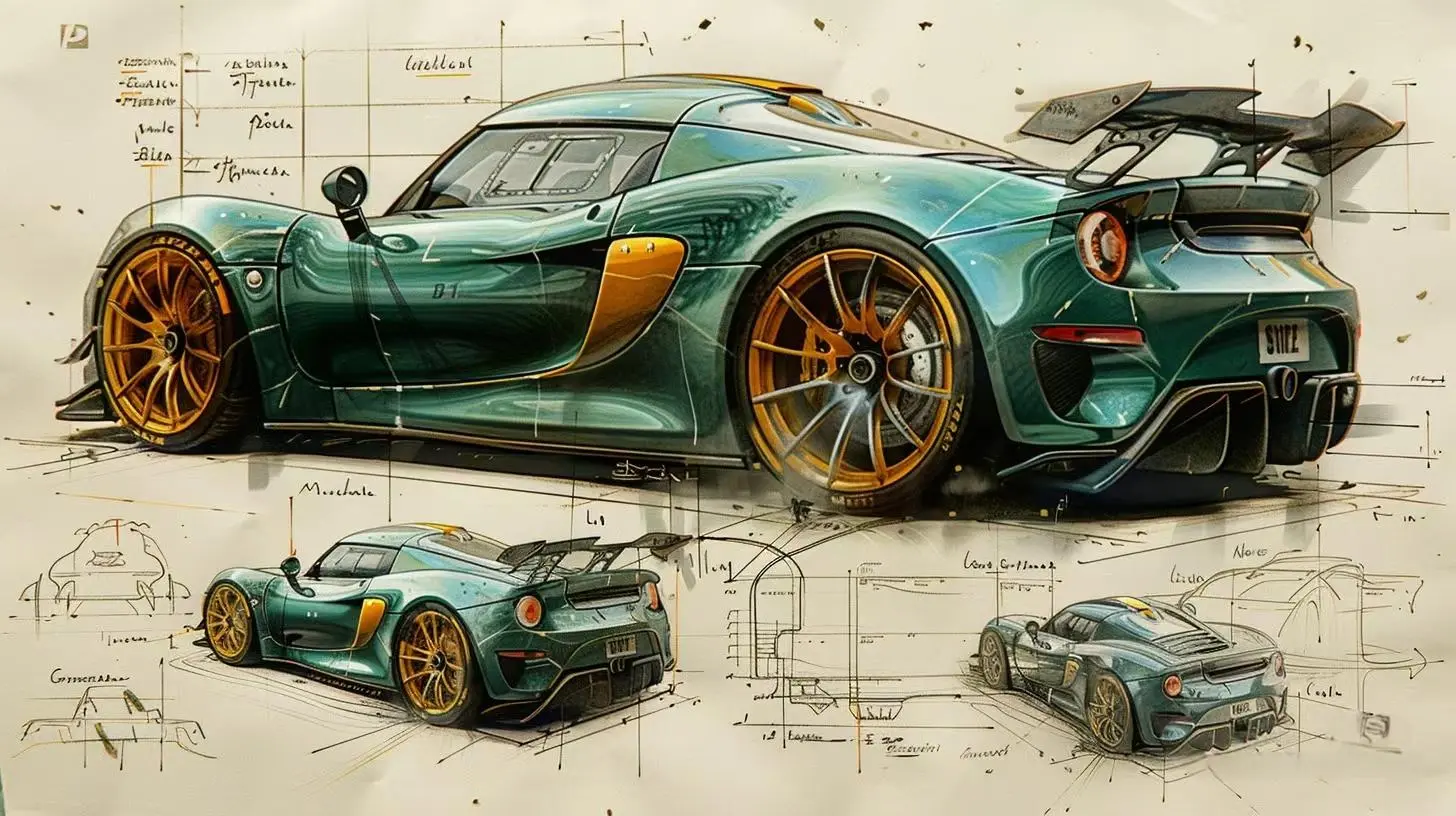

A robust design that achieves the ideal of light and sporty driving, it is the combination of strength, lightness and beauty.

Classic Wheels

RWM-11Y|

RWM-16L |

RWM-18B|

Forged wheels VS Cast wheels

| No. | Item | Description |

| 1 | Manufacturing process | Casting wheel is a wheel hub obtained by casting liquid metal into a mold, cooling it, polishing it, and other subsequent processing techniques. There are mainly three manufacturing processes: gravity casting, low-pressure casting, and rotary casting, among which low-pressure casting is the most common process. Forging wheel is the process of applying pressure to metal blanks using a forging press to produce plastic deformation and obtain forgings. The manufacturing process of forging wheel hubs is relatively complex, including multiple steps such as forging, spinning, and lathe processing. |

| 2 | Appearance and weight | Cast wheels and forged wheels are difficult to distinguish in appearance, but cast wheels are generally about 20% heavier than forged wheels. |

| 3 | Performance | The metal molecules of the forged wheel are closely arranged, so their toughness, impact resistance, strength, and load-bearing capacity are relatively high. The arrangement of metal molecules in the cast wheel is relatively loose, and its performance is slightly inferior to that of the forged wheel. |

| 4 | Cost | The manufacturing process of casting wheel is relatively simple, suitable for mass production, and has lower costs. The manufacturing process of forging wheel is complex and requires expensive forging equipment, resulting in higher costs. |